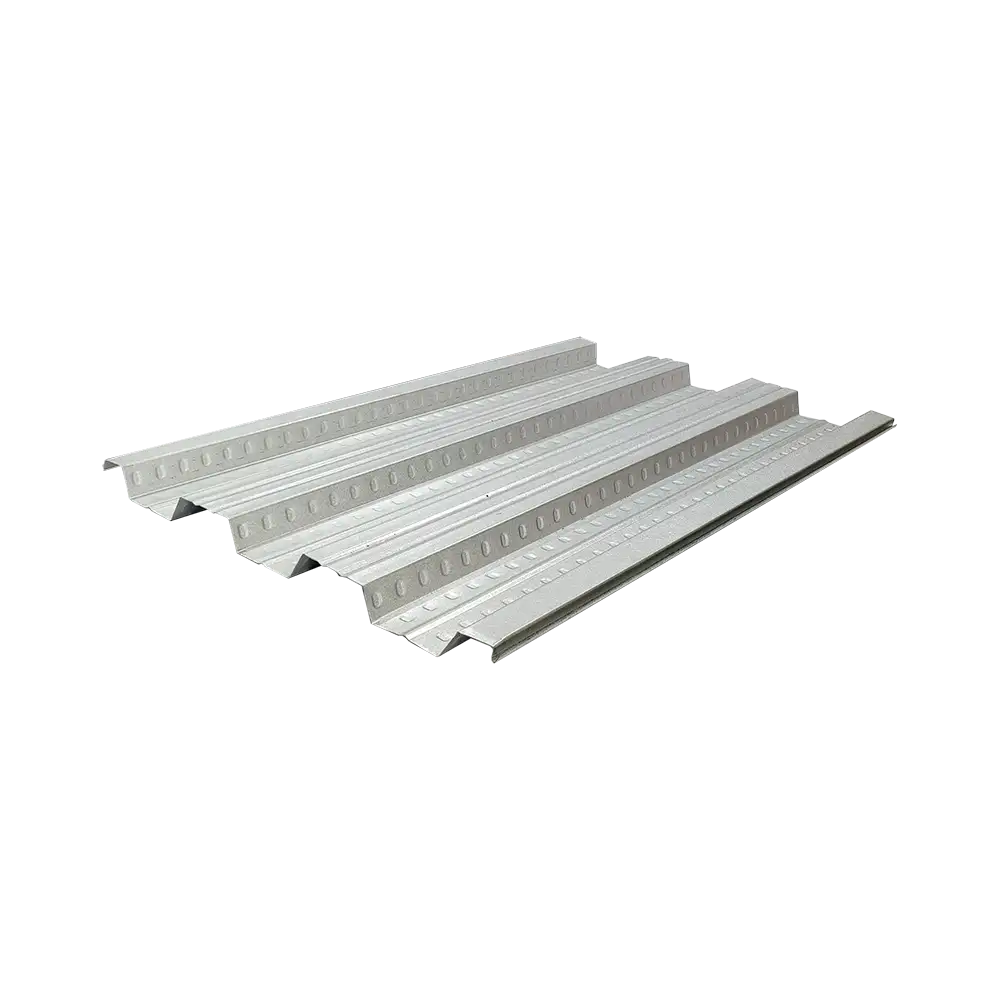

TH Floor Deck 51 (Structural Composite Decking)

RM0.00

TH Floor Deck 51 is an advanced trapezoidal composite flooring system designed as a permanent formwork that for efficient construction, providing a robust solution for a variety of building applications.

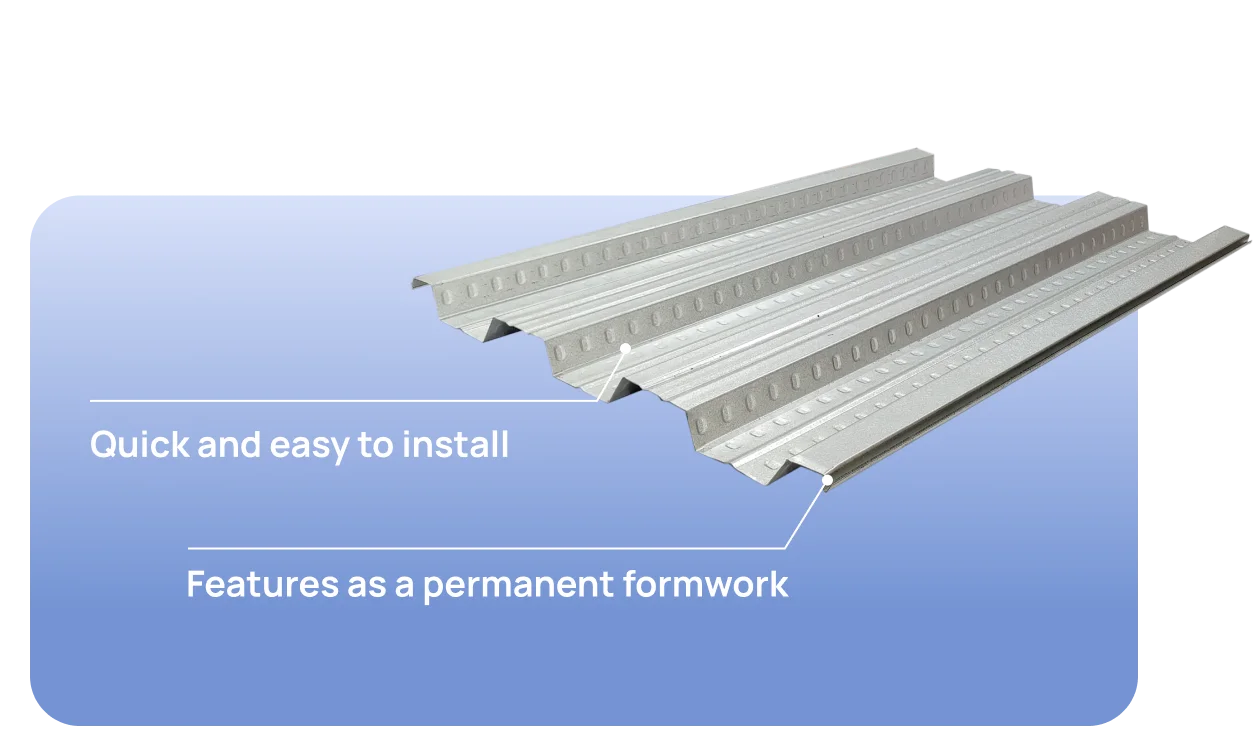

- Quick installation without the need for temporary supports.

- Reduces slab depth and concrete usage.

- Enhanced structural integrity

Rapid Installation and Construction Efficiency

Designed for quick installation without the need for temporary supports, TH Floor Deck 51 accelerates the construction process, allowing for immediate progression to subsequent floor levels.

Designed for rapid installation without the need for temporary supports, facilitating faster project completion.

The unique profile minimises slab depth and concrete usage, lowering overall weight and construction costs.

Provides a stable and safe working surface, allowing for continuous construction without delays.

No Additional Premature Formwork Needed

Streamlines the building process, reducing the need for premature formwork removal and improving floor quality.

High Tensile Strength

Made from high tensile steel with a minimum yield strength of 550 MPa, ensuring durability and structural integrity.

Simplified Handling and Storage

Designed for easy handling and storage, reducing the risk of damage and ensuring efficient onsite management.

Quality Assured

Driven by visionary leadership and an unwavering commitment to quality, Thung Hing has consistently pushed the boundaries of innovation in the construction industry. Our dedication to delivering exceptional products and services has earned us numerous accolades, solidifying our position as a market leader.

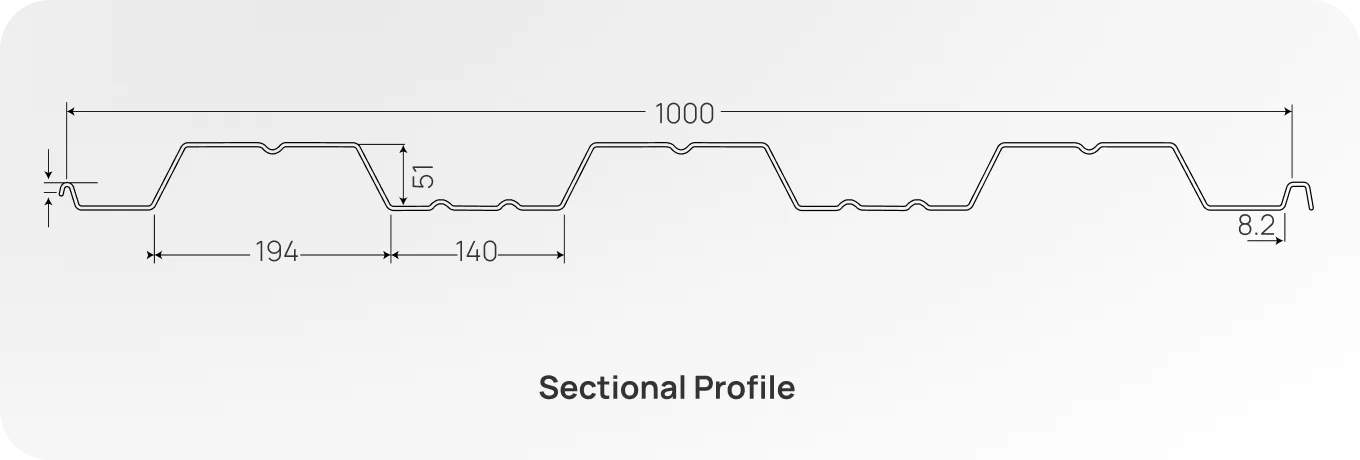

Specifications

Dimension Details

Tolerance

Length

Cover

Thickness

: ±10mm

: ±10mm

: ±0.02mm

Download TH Floor Deck Catalogue

Get a quote

Let’s talk about your project

- Let us understand your requirement and let our roof specialist customise a solution for you.

- 1-to-1 meeting to discuss how our products and solutions can help in your project.

Related products

-

TH Floor Deck 75 (Structural Decking)

RM0.00TH Floor Deck 75 is a robust and efficient structural decking system designed as a permanent formwork for composite concrete, masonry, or steel frame construction, offering excellent spanning capacities and cost-effective performance.

- Excellent spanning capacity with reduced bending

- Composite slab design saves on concrete and reinforcement.

- Patented corner embossments enhance strength and bonding.

- Durable, high-tensile, zinc-coated steel construction.